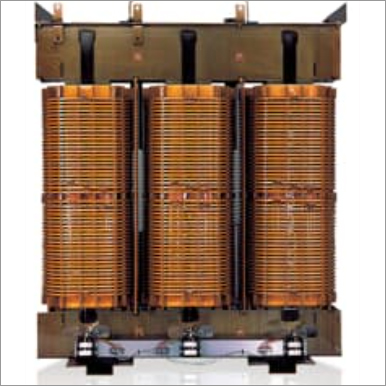

Vpi Dry Type Transformers

Price 900340 INR/ Unit

Vpi Dry Type Transformers Specification

- High Voltage

- 3.3 kV 33 kV

- Cooling Type

- AN / AF (Air Natural / Air Forced)

- Low Voltage

- 0.415 kV 11 kV

- Rated Voltage

- Up to 33 kV

- Operating Temperature

- -25C to +105C

- Capacity

- 100 kVA to 2500 kVA

- Standard

- IS 11171 / IEC 60076

- Load Loss

- As per IS 1180 / IEC 60076

- Dimension (L*W*H)

- As per specific rating (Customizable)

- Coil Material

- Copper / Aluminum

- Product Type

- VPI Dry Type Transformer

- Material

- Copper / Aluminum

- Output

- Customizable as per requirement

- Frequency (MHz)

- 50-60 Hz

- Efficiency

- 98-99%

- Phase

- Three Phase

- Usage

- Electrical Power Distribution

- Coil Structure

- Laminated Core

- Coil Number

- Three

- Power Scope

- Upto 2500 kVA

- Weight

- Variable as per rating, approx. 800 kg - 5000 kg

- Insulation Class

- Class F / Class H

- Winding Type

- Vacuum Pressure Impregnated (VPI)

- Fire Resistance

- Self-extinguishing insulation

- Applicable Industries

- Industrial, Commercial, Hospitals, Data Centers, Renewables

- Noise Level

- Less than 60 dB

- Protection Class

- IP23 / IP44 (optional)

- Testing

- Routine and Type tested as per IS / IEC standards

- Short Circuit Impedance

- 4% 6%

- Humidity Resistance

- Up to 95% RH

- Service Life

- > 25 Years

- Mounting Type

- Floor Mounted

- Ambient Temperature Range

- -25C to +50C

- Thermal Overload Capacity

- Up to 150% for short duration

- Tap Changer

- Off-circuit or On-load (Optional)

Vpi Dry Type Transformers Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Others

- Main Domestic Market

- All India

About Vpi Dry Type Transformers

Superior Safety and Durability

VPI Dry Type Transformers come equipped with self-extinguishing insulation and protection classes IP23/IP44, making them ideal for environments where fire safety and electrical integrity are paramount. Their rugged design resists humidity up to 95% RH and functions efficiently in ambient temperatures ranging from -25C to +50C.

Customizable Power Distribution

With capacities ranging from 100 kVA up to 2500 kVA and customizable output configurations, these transformers meet the diverse needs of industries, commercial buildings, hospitals, and data centers. The flexible mounting options and phase selections allow easy integration into new or existing power infrastructure.

Compliant and Efficient Performance

Manufactured according to IS 11171 and IEC 60076 standards, these dry type transformers undergo rigorous routine and type testing. Their low load loss and high efficiency (98-99%) ensure economical and reliable power distribution even in demanding operational scenarios.

FAQ's of Vpi Dry Type Transformers:

Q: How does the VPI process enhance transformer performance?

A: Vacuum Pressure Impregnation (VPI) improves the winding insulation by thoroughly embedding it with resin under vacuum, reducing the risk of moisture ingress and enhancing thermal performance, leading to longer service life and improved reliability.Q: What environments are suitable for installing these dry type transformers?

A: These transformers are suited for industrial, commercial, hospital, data center, and renewable applications. Their IP23/IP44 protection, humidity resistance up to 95% RH, and robust temperature range ensure safe operation in both indoor and outdoor settings.Q: When should a tap changer be opted for, and what types are available?

A: Tap changers are recommended when voltage adjustment is necessary for load variation. Both off-circuit and on-load tap changer options are available, allowing users to select based on operational needs and convenience.Q: Where can the transformers be installed, and what mounting options are provided?

A: The VPI Dry Type Transformers are designed for floor-mounted installation, offering versatility for placement in substations, electrical rooms, or dedicated transformer bays in industrial and commercial settings.Q: What is the typical process for routine and type testing of these transformers?

A: Routine and type testing are conducted as per IS 1180, IS 11171, and IEC 60076 standards. Tests include load loss measurements, short circuit impedance validation, insulation resistance checks, and verification of fire resistance and efficiency before shipment.Q: How does using self-extinguishing insulation benefit users?

A: Self-extinguishing insulation significantly enhances fire safety by rapidly suppressing flames in case of electrical faults, minimizing damage and potential risks, making these transformers suitable for critical environments like hospitals and data centers.Q: What is the expected operational life and maintenance requirement for these transformers?

A: Engineered for a service life exceeding 25 years, these transformers require minimal maintenance due to their robust design, high-quality materials, and durable insulation, ensuring long-term and reliable power distribution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Transformers Category

Power Transformers upto 10 MVA- 33 kV Class as per IS 2026 and IEC 60076

Price 959000 INR / Unit

Minimum Order Quantity : 01 Unit

Product Type : Other, Power Transformer

Frequency (MHz) : 50 Hz

Rated Voltage : Up to 33 kV

Usage : Industrial/Utility Power Distribution and Transmission

Special Designed Transformers

Price 550000 INR

Minimum Order Quantity : 01 , , Unit

Product Type : Other, Special Designed Transformers

Frequency (MHz) : 50/60 Hz

Rated Voltage : 11 kV / 33 kV / Custom

Usage : Industrial, Power Distribution, Control Panels, Custom Applications

Single Phase Distribution Transformers Up to 25 KVA as per IS 1180

Price 550000 INR

Minimum Order Quantity : 01 Unit

Product Type : Other, Distribution Transformer

Frequency (MHz) : 50 Hz

Rated Voltage : 11 kV / 0.433 kV

Usage : Power Distribution

Cast Resin Dry Type Transformers

Price 550000 INR

Minimum Order Quantity : 01 Unit

Product Type : Other, Cast Resin Dry Type Transformer

Frequency (MHz) : 50/60 Hz

Rated Voltage : Up to 33 kV

Usage : Electrical distribution and power supply in commercial, industrial, and utility installations

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese